High end manufacturing

Complying with the requirements of the era of Industry 4.0, HUIJIN has established a modern manufacturing center, which owns manufacturing workshops for machining, sheet metal processing, product assembly and auxiliary supporting facilities, fully realizes digital production from product design, manufacturing processing and product assembly. It has sheet metal processing centers, machining manufacturing centers and assembly centers that are at the international and domestic advanced levels. It has systematically mastered the core technologies of key processes, tooling, and assembly, able to produce large-scale of high-precision key components and electromechanical components. HUIJIN mainly designs, develops and produces various precision machinery and sheet metal products for large and medium-sized enterprises, mainly serving for the rail transit industry, financial equipment industry, intelligent file management industry, intelligent retail equipment, network communication industry, etc.

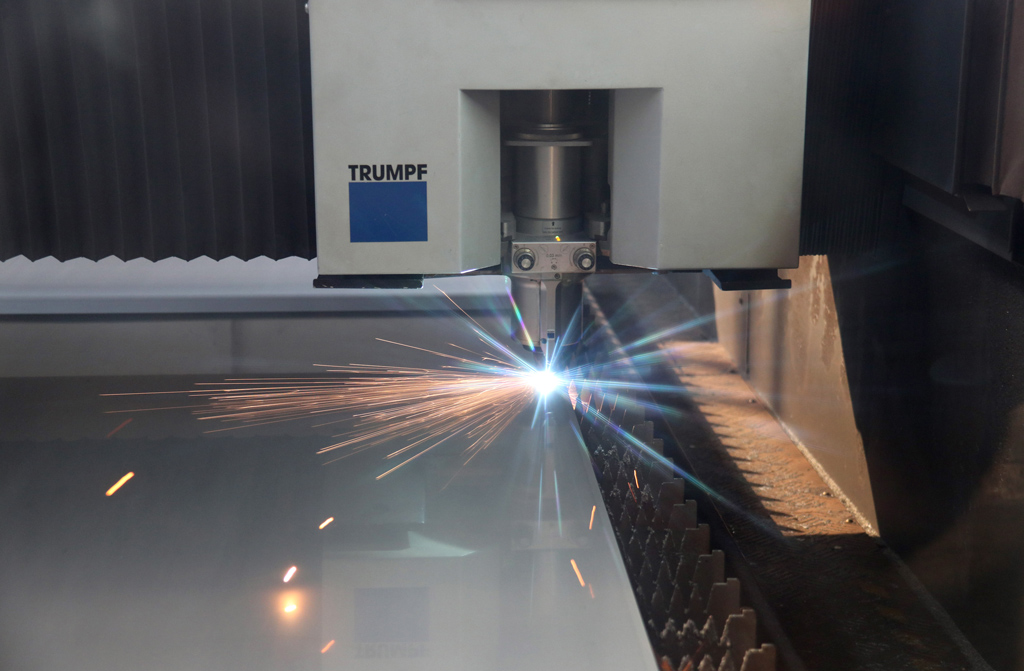

HUIJIN is a domestic sheet metal processing enterprise that has introduced the world's most advanced German automated production system. HUIJIN has invested a total of 80 million yuan to purchase more than 100 sets of foreign imported equipment such as German TRUMPF, Japan's Armada, Sweden's Sidan, American Hager, American Nordson. It has machining center, drilling and tapping center, CNC lathe, turning and milling center, four-axis machining center, general turning, general milling, tool milling, surface grinding, cylindrical grinding, tool grinding, centerless grinding, wire cutting fast wire / medium wire , fitter, placement machine, terminal block machine and other diversified equipment, accumulated to more than 100 sets of various types of machinery and equipment including Japan's Mazak (MAZAK) series, Germany's DMG series, American Haas (HASS) series, South Korea's Hyundai Wia There are nearly 50 sets of imported equipment.

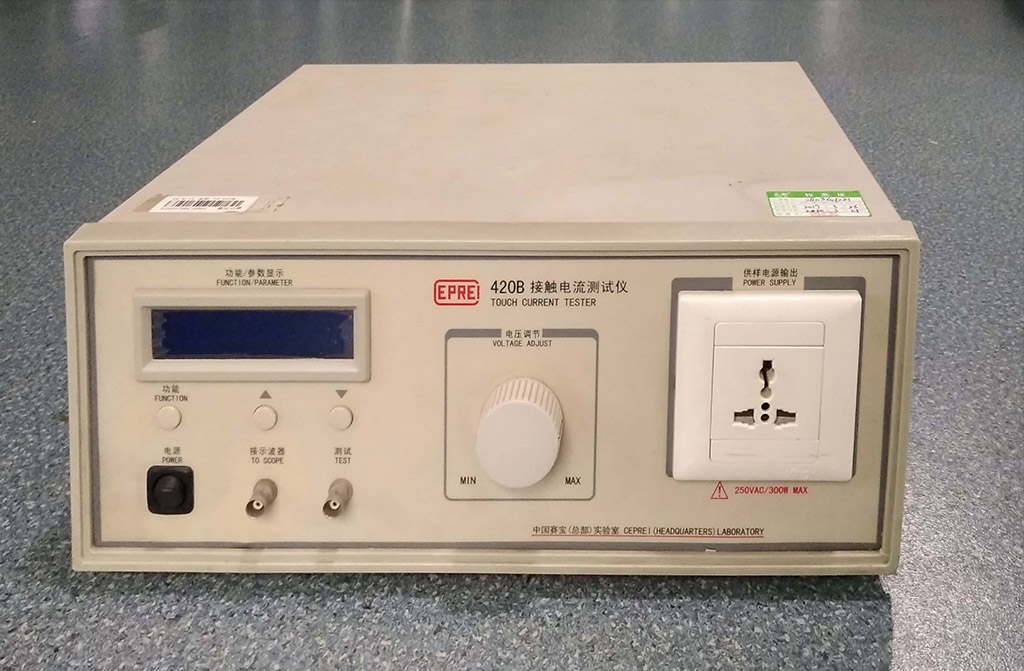

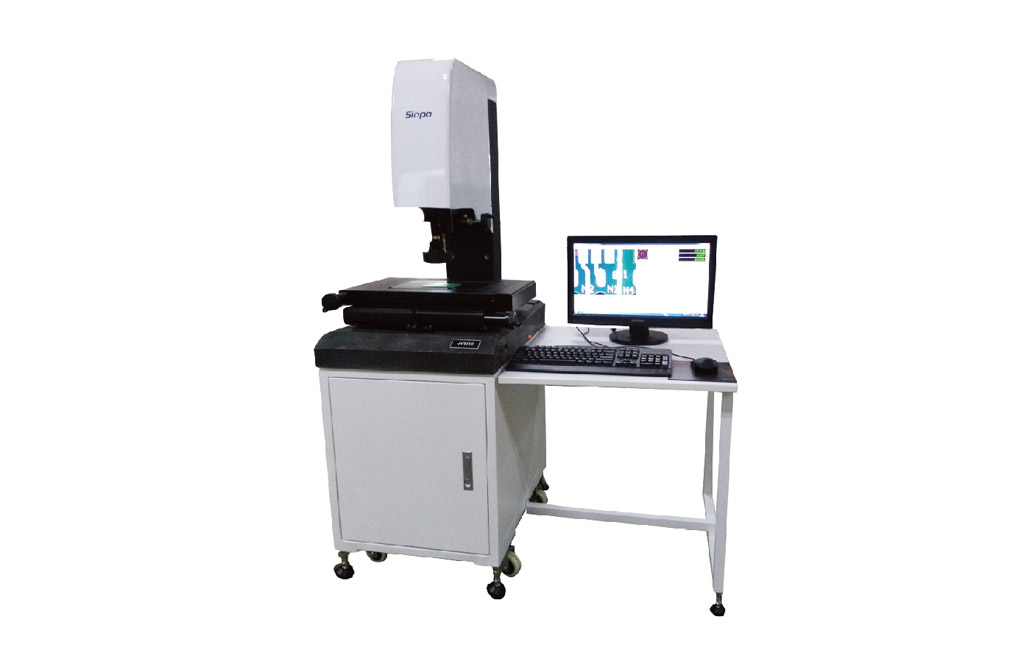

During the production process, HUIJIN has established a complete quality management system and various testing equipment, including inspection work flow, testing equipment management, product testing, quality problem handling, assessment system, etc. We have established a complete inspection standard document. The implementation of the inspection is carried out in strict accordance with the corresponding system and inspection instructions to ensure product quality.

Sheet Metal Processing Capability

The sheet metal automatic processing center is mainly used for mass production of high-precision sheet metal products. The laser system is capable of cutting, welding, and laser cladding. It can process various profiles and provide scratch-free laser cutting and blanking. Competent for a variety of simple or complex forming processes, excellent cutting accuracy to ensure cutting quality, automatic bending robots can achieve automatic photography, positioning, bending, stacking, automatic loading and unloading devices, automatic sorting devices and storage. The finished product provides the raw material storage device, which can be combined with each other to realize a fully automated production mode. Our company has 15 imported and domestic leading bending machines that can meet various bending needs, and can achieve the business needs of processing lengths from 1mm to 10m, processing thicknesses of 0.2mm and 15mm, and processing accuracy of ┬▒0.1mm.

Welding capability

The company invested a total of 18 sets of hanging electric welding machines, TRUMPF fiber laser welding robots, Panasonic argon arc welding robots, and cylinder longitudinal seam and circumferential seam welding machines, and formed a professional welding team, including international welding engineers. 2 people, 2 welding technicians, and 30 professional welding personnel with international welder qualification certificates. The team strictly follows the ISO3834 international welding quality management system certification standard and EN15085 European rail vehicle and its components welding quality management system certification standard. Product quality and safety.

After-sales service capability

The company strictly follows the IRIS international quality management system, has a complete after-sales service system, tracks the use of each product at regular intervals, provides 24-hour service response, and provides customers with all-round, all-weather after-sales service . The company's products are sold all over the country and overseas, and have withstood the severe test of various conditions. The operation is in good condition, and no accidents have occurred. The qualified rate of the products is 100%, and the customer satisfaction rate is 95%, which is highly praised by users. The company has always been adhering to the customer as the focus, insisting on technological innovation to strengthen and improve the quality management system, to provide customers with satisfactory high-tech products.